CONCRETE ADMIXTURES

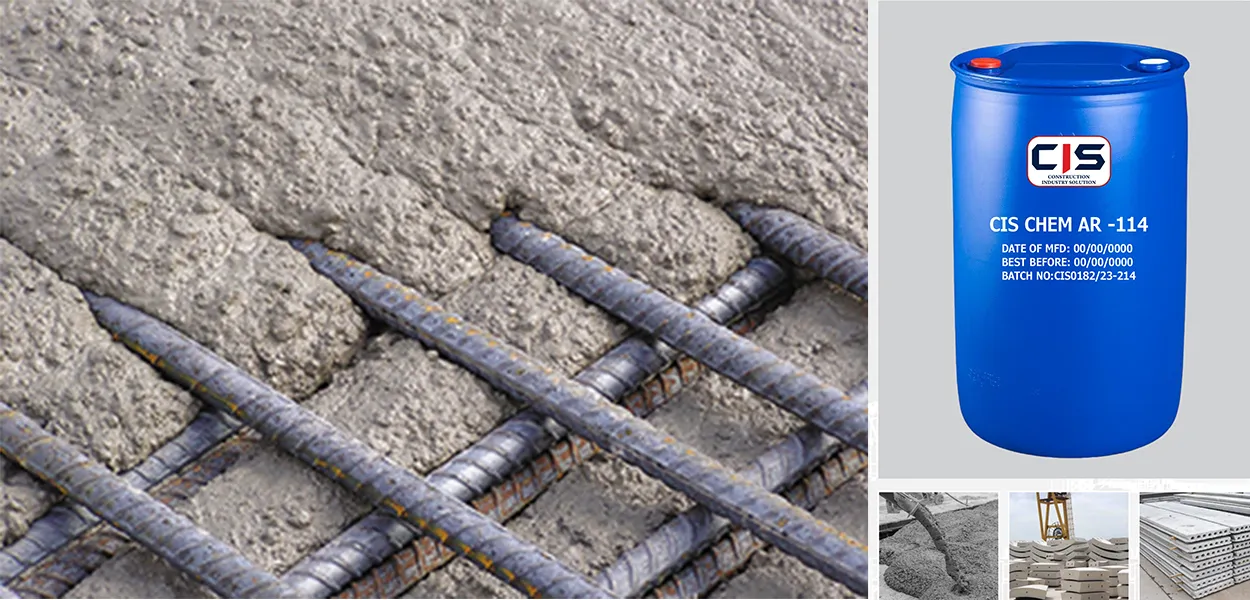

CIS CHEM AR-114

HCORROSION INHIBITING ADMIXTURE

PRODUCT CATEGORY: POLYCARBOXYLIC ETHER BASED ADMIXTURE

CIS (Construction Industry Solution) is one of the most prominent names in the list of concrete admixtures suppliers in Mumbai. We manufacture and supply high-quality products that not only increase the strength of the concrete but also the durability and overall performance of the concrete for all kinds of construction projects. Workability is one of the problems our concrete admixtures solve. They are so designed that they will lower the water consumption and that the setting time will be faster or slower, as required, and in this way they give top results in residential, commercial, and industrial applications.

Being amongst the best concrete admixtures suppliers in Mumbai, CIS is committed to offering the most innovative, affordable, and the most dependable solutions to the builders, contractors, and architects to meet their ever-changing requirements. Acclaimed for their quality and the same quality all the time, CIS is among the leading concrete admixtures suppliers in Mumbai who have made products that assure longevity and sustainable construction. The need for hard work and dedication always pays off and that is what CIS stands for. Rely on CIS for services that are excellent and opt for us as your preferred concrete admixtures suppliers in Mumbai.

Product Discription

CIS CHEM AR 114 is NON BIOPOLAR nitrite,migrating corrosion inhibiting admixture thatprotects rebars from corrosion induced by chlorideions as well as due to carbonation of concrete

Uses

Steel reinforced concrete in marine zones

- Piers, piles, and concrete dock structures

- RCC structures exposed to corrosive environments

- Bridges, highways, chlorinating plants, sewerage systems

- Adds corrosion inhibition properties to cementitious grouts

Characteristics / Advantages

Simultaneous cathodic and anodic protection of steel

- High penetrating power resulting in total protection of rebars or PT tendons

- No adverse effect on properties of hardened concrete or grout

- Effective even in presence of high amount of chlorides

- Eco-friendly, nitrite and chromate free

- High alkalinity offers additional protection to steel A

-

CIS CHEM FLOW -110

-

CIS CHEM FLOW -112

-

CIS CHEM LPC -120

-

CIS CHEM MPC 121

-

CIS CHEM HPC 124

-

CIS CHEM HSR-135

-

CIS CHEM SUPERPLAST -120

-

CIS CHEM AR-114

-

CIS CHEM QG -138

-

CIS CHEM SHORTCRETE -142